Ansys Implementation

Where research begins: Expert guidance on topic selection.

Ansys Implementation

John Swanson established Swanson Analysis Systems, Inc. (SASI), the precursor to Ansys, in 1970. Swanson first had the idea for Ansys in the 1960s while he was employed at the Westinghouse Astronuclear Laboratory. Engineers used to conduct finite element analysis (FEA) by hand. Swanson left Westinghouse in 1969 to pursue his own software development when the firm rejected his concept to automate FEA through the development of general purpose engineering software. The following year, he established SASI and operated from his Pittsburgh farmhouse.

Swanson utilised a mainframe computer which were rented by the hour and created the first ANSYS software using punch cards. He was hired as a consultant by Westinghouse with the understanding that every code he wrote for the company might also be used in the Ansys product aspect. The first company to employ Ansys was Westinghouse.

In 1994, Swanson sold venture capitalists his stake in the business, which was then renamed Ansys in honour of the software. In 1996, Ansys went public on the NASDAQ. The business obtained more technologies for fluid dynamics, electronics design, and physics analysis in the 2000s by acquiring other engineering design firms. The NASDAQ-100 index included Ansys on December 23, 2019. ANSYS is a multipurpose software that employs many numerical modelling methods. However, learning can be challenging at times, particularly for newcomers or even designers who are typically not experts in finite elements.

With ANSYS Workbench, an attempt has been made to provide a software that is very user-friendly and has the best ANSYS algorithms incorporated by default.One of the most popular finite element software packages available today, ANSYS has numerous engineering applications. Numerous engineering disciplines, including coupled field issues, electromagnetics, fluid flow, heat flow, dynamics, and statics have finite element solutions accessible.

It is common knowledge that a finite element solution is basically an approximation of the challenge being solved, and that one must always determine if it is a terrible or good solution. Therefore, how can a finite element solution be verified? Even though ANSYS provides a good number of warnings to help the user avoid making modelling errors, there are still some aspects of pre- and postprocessing as well as the solution process that we would like to talk about to highlight the instances in which user knowledge may still be required to get good results.

The most widely used simulation technique for predicting the physical behaviour of structures and systems is the finite element method (FEM). Numerical approaches have evolved to find solutions for the governing equations of specific situations because analytical solutions are generally not available for most everyday problems in the engineering sciences. Originally developed for the solution of structural mechanics problems, the finite element approach finds use nowadays in many other engineering domains where the physical description yields a mathematical formulation with a few standard differential equations which may be solved numerically.

Over the past thirty years, a great deal of research has been done in the subject of numerical modelling, allowing engineers to do simulations that are quite accurate today. Large deformations, nonlinear material behaviour, and contact issues are examples of nonlinear phenomena in structural mechanics that are now common modelling jobs. These days, simulations can be run even for models with millions of degrees of freedom, because to the hardware industry’s rapid progress, which has produced ever-more-powerful CPUs and cheaper memory.

From a mathematical perspective, the finite element solution provides only an approximative numerical solution for the problem under consideration. Determining whether a solution is good or terrible can be a challenging challenge for an engineer at times. A finite element result can be readily verified if experimental or analytical results are provided. However, each user of a finite element software should have some previous knowledge about the finite element approach in general in order to forecast any structural behaviour in a trustworthy manner without the need for trials. To assess the suitability of the selected elements and algorithms, he should also possess a basic understanding of the used programme.

ANSYS is a multipurpose software that employs many numerical modelling methods. However, learning can be challenging at times, particularly for newcomers or even designers who are typically not experts in finite elements. Some work has gone into providing ANSYS Workbench, a tool that is very easy to use and has the best ANSYS algorithms installed by default.

Engineering simulation software for usage across the product life cycle is created and marketed by Ansys. The fluid flow, electromagnetism, temperature distribution, elasticity, toughness, strength, and similar features of machine components, electronics, or computer models of structures are analysed using Ansys Mechanical finite element analysis software. Ansys is used to forecast a product’s behaviour under specific scenarios without the need to build test products or conduct crash tests. For instance, Ansys software can be used to predict a bridge’s performance over many years of operation, determine the least amount of waste from canning fish, or design a safer yet less material-intensive slide.

Most Ansys simulations are done using Ansys Workbench, one of the company’s main products. Typically, Ansys users break down big structures into smaller parts, each of which is separately modelled and tested. It is possible to establish an object’s dimensions first, and then add temperature, pressure, weight, and other physical properties.Lastly, the Ansys programme simulates and analyses a variety of phenomena throughout time, including electromagnetic efficiency, temperature distribution, fluid flow, fatigue, fractures, movement, and other effects.

Additionally, Ansys creates software for teaching, data management and backup, and academic research. Ansys software is offered for purchase as a yearly subscription.

Ansys Discovery need to be at the top of your list if you’re searching for simulation software that can offer interactive modelling and simulation features in addition to proof-of-concept. Ansys Discovery is designed to assist in providing early answers to important design queries while examining several options for your concept before prototyping.

Compared to other Ansys solutions, Discovery requires less computing power and can serve as an excellent starting point for internal simulation projects. Because of its special solving technology, it may be a GPU-intensive programme

Other Services

- PHD & POST DOC Admission counselling

- Topic Section

- Review Paper Writing

- Systematic Literature Review (SLR)

- Research Paper Writing

- Synopsis Writing/Pre thesis writing

- Thesis Writing

- Data Analysis

- Questionnaire Preparation

- Developing Research Framework

- Methodology Development

- MATLAB Implementation

- Matlab Simulation

- Python Implementation

- Machine Learning Implementation

- Deep Learning Implementation

- VHDL Implementation

- Hadoop

- NS2 Implementation

- NS3 Implementation

- ArcGis Mapping & Analysis

- Spss Data Analysis

- Stata Data Analysis

- Amos Analysis

- R Programming

- E-Views Data Analysis

- Minitab Data Analysis

- Software Testing

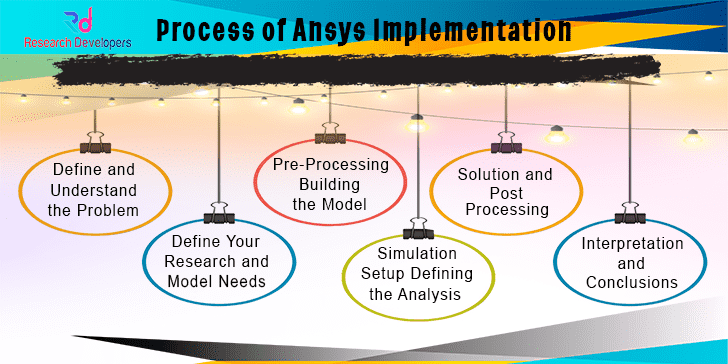

- Ansys Implementation